At

its very core, Dynamo is building turbo machinery. A very simple device made complex by time and

design. The first turbines were built as

early as Hero of Alexandria in the 1st century, yet with the advent of steam

power, and the ever increasing need to do more work with less fuel in a tighter

footprint, the turbine has become ever more complex.

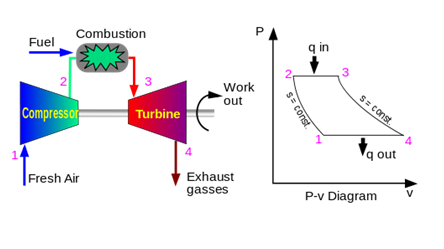

To

explain how the Dynamo Turbocore works, we first must learn a basic fact about

engines. Engines do work, which is

really a force over a distance (or a torque over an angle). To get this useful work, typical engines

complete a cycle (to allow you to get work over and over again). By pushing on a fluid, adding heat, and then

letting the fluid expand, and using that expansion to drive mechanical motion,

some of the energy in the heat can be used to produce useful work—like lifting

water or pushing a car.

Gas

Turbines do this in a very simple way.

Air is accelerated by a compressor wheel, and then slowed down in a

stationary passage to convert velocity to static pressure. Then heat is added in a combustion chamber,

which expands the air and increases the volumetric flow rate. Then the hot air is accelerated through a set

of nozzles, and then a turbine gets pushed by this fast moving air, and pulls

out some of the kinetic energy. In the Dynamo

Turbocore, there are two such turbines, the first one is used to power the

compressor, and the second generates shaft power for us to use. The compressor creates the push (force /

area) while the air flowing through the engine is the volume (length *

area). For those of you keeping track,

you will know that the volume passing through the turbine is greater than the

volume flowing through the compressor—this is another way to interpret why heating

the air creates more net power.

Gas

turbines like the Turbocore can be made more efficient by adding multiple

compressors or spinning the compressors faster to increase the pressure, and they

can be made more powerful by using bigger compressors to flow more air (and

volume) through the engine.

So

that takes care of the mechanical portions of the engine. But of course, this doesn’t explain how we

take power from a rotating turbine and convert that into useful

electricity—more on this next week.

No comments:

Post a Comment